About Us

Leading Manufacturing Company

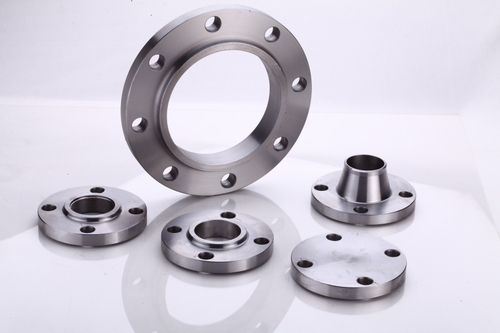

Ritech Engineering , the company is concentrating on piping solutions for industrial companies. We are located in India, equipped with multi-base inventory and manufacturing facilities in Rajkot India. We have large in-stock of different material with carbon, alloy, and stainless steel flange and raw material flange plate, which means we can manufacture your specific requirements in the urgent period.

We supply different forged steel flange material standards in ASTM A105, ASTM A182, ASTM A350, ASTM A694, ASTM A516, Manufacturing standards in ASME B16.5, ASME B16.47, ASME B16.36 and etc.

Smart Technology

Using Smart Way to Manufacturing Process

Best & Leading Industrial Supplier

Our Advantages

-

QUALITY OF THE PRODUCT

We ensure that the quality standards are met. Hence, as per customers requirement, we supply products of standard quality after going through various checking, testing, inspection & certification process.

-

QUALITY RAW MATERIALS

All the material used for Manufacturing of fittings are tested for chemical & mechanical properties. They are identified & fully traceable from raw material stage to final product.

-

CHECKS & CONTROLS

The system controls the quality of all incoming materials as per the raw material test certificate. Randomly checking in each size for chemical and physical properties at Government approved laboratory

-

TESTING & INSPECTION

Quality Forge Fittings maintains strict dimensional standards by inspecting and testing equipmentwith strict adherence to the quality manual. All our finished material is inspected for quality after the first piece of a production.

-

LEADING SUPPLIER

As ISO 9001:2015 Certified Company, we are the leading manufacturer and suppliers of all types of high quality Stainless Steel, Pipe Fittings, Butt weld and Forged Fittings and Flangers.

-

CERTIFICATION

Fittings are supplied with test certificates as approved QAP which includes chemical composition, mechanical properties, hardness details of heat treatment and stamping details.